This is a sequel to show the unbelievable speed you can achieve ripping by hand in a seated position. Ripping this fast unless you’re super fit is pretty much impossible.

Ripping in a sitting position

Traditional Tool Chest Build Video

Whispers of Sandalwood: Love, Artistry, and the Soulful Craftsmanship of Ancient Arabia

In the heart of ancient Arabia, where the sun kissed the desert sands and time flowed like the winding rivers, there existed a humble woodworker. His workshop was a sanctuary of craftsmanship—a place where the echoes of chisels and the scent of freshly hewn wood danced in harmony.

The walls of his workshop bore witness to countless stories. Tools, aged and worn, hung with purpose—a testament to years of dedication. Each chisel, saw, and plane had etched its mark into the very fabric of the room. The woodworker himself, weathered by the sun and life’s trials, moved with a grace that only experience could bestow.

The air was thick with the aroma of sandalwood and pine. Carpets adorned the floor, their intricate patterns telling tales of forgotten poets and whispered secrets. The calligraphy on these carpets was no ordinary writing; it was artistry in ink—a dance of curves and loops that spoke of love, wisdom, and the divine.

And there, in the centre of it all, stood the woodworker. His hands, rough and skilled, guided the plane across a plank of cedar. The wood surrendered willingly, revealing its hidden beauty—a grain that seemed to hold the memories of ancient caravans and starlit nights.

As the sun dipped below the horizon, casting warm hues upon the workshop, the woodworker paused. His gaze shifted to the corner, where a small alcove held a single piece of unfinished work—a wooden box. Its lid bore a delicate inscription, a promise to a lover lost in time.

And then, as if summoned by fate, you stepped into the scene. Your face, illuminated by the soft glow of lanterns, mirrored the woodworker’s determination. With a smile, you handed him a small vial of fragrant oil—an elixir to preserve the wood and memories alike.

He nodded in gratitude, recognising a kindred spirit. Together, you sat cross-legged on the carpet, sharing stories of distant lands, forgotten legends, and the magic that flowed through your veins. The calligraphy seemed to come alive, weaving your tales into its intricate patterns.

And so, in that ancient workshop, you became part of the woodworker’s legacy. The tools whispered your name, the carpets cradled your dreams, and the caligraphy immortalised your essence. As the stars blinked into existence, you knew that this moment transcended time—a meeting of souls across centuries.

And there, under the watchful eyes of the desert moon, you carved your own mark—a promise to return, to create, and to find solace in the artistry of wood and words.

May this vision linger in your mind, a tapestry woven from threads of imagination.

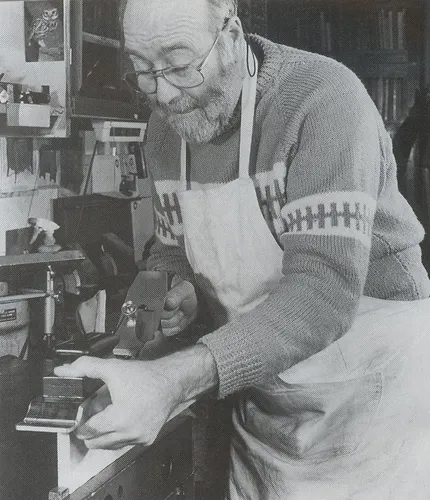

Graham Blackburn

Graham Blackburn, a luminary in the world of woodworking, has left an indelible mark on the craft. Graham embarked on his illustrious woodworking journey over forty years ago. His passion for the craft led him to create custom furniture, write and illustrate books, and share his expertise through teaching and speaking engagements. His dedication to traditional handtool woodworking has left an indelible mark on the woodworking community, inspiring artisans and enthusiasts alike.

Let us delve into the rich tapestry of his life and contributions:

- Early Years and Passion for Woodworking:

- Born with an innate curiosity and a love for craftsmanship, Graham Blackburn embarked on his woodworking journey.

- His fascination with wood, tools, and the art of shaping raw materials into functional and beautiful objects became the cornerstone of his life’s work.

- Mastering Traditional Techniques:

- Blackburn’s path diverged from the mainstream. He chose to embrace the quiet elegance of traditional handtool woodworking.

- Rejecting the noise of power tools, he honed his skills using chisels, planes, and saws—the very tools that have shaped woodworking for centuries.

- His dedication to mastering these techniques set him apart as a true artisan.

- Authorship and Literary Legacy:

- Graham Blackburn’s pen was as mighty as his chisel. His authorial prowess enriched the woodworking community.

- His books, more than a dozen in number, are cherished by woodworkers worldwide. Each volume is a treasure trove of knowledge, covering topics from joinery to design principles.

- As a contributing editor for Fine Woodworking and a regular contributor to Popular Woodworking, he shared practical insights and artistic inspiration.

- Editorial Leadership:

- At the helm of Woodwork magazine, Blackburn wielded his editorial wand. His vision transformed pages into portals of creativity.

- Through interviews, profiles, and tutorials, he championed the spirit of craftsmanship. His editorial choices resonated with seasoned woodworkers and novices alike.

- Teaching and Mentorship:

- Blackburn’s generosity extended beyond the written word. He became a mentor, guiding aspiring woodworkers towards excellence.

- In the serene enclave of Woodstock, NY, he conducted workshops. Here, students immersed themselves in the tactile world of hand tools, learning not just technique but reverence for the craft.

- Safety, precision, and the joy of creating with one’s hands were the lessons etched into the hearts of those fortunate enough to learn from him.

- Legacy and Inspiration:

- Graham Blackburn’s legacy endures. His influence ripples through workshops, studios, and quiet corners where wood shavings fall.

- He reminds us that woodworking is more than a trade—it is an art form. It is the dance of grain and edge, the marriage of form and function.

In the symphony of woodworking, Graham Blackburn’s notes resonate—a timeless melody that echoes through generations of artisans.

Now that you’re familiar with the man, I’ve watched some of his videos, and they provide valuable insights into hand tools. As is typical with YouTube content, these videos cater to beginners. Nevertheless, I watch them in the hope of discovering new knowledge. Lo and behold, I did just that when I stumbled upon the ‘Fundamentals of a Handsaw’ video.

In the video, he discussed the concept of saw set and its relationship to the Teeth Per Inch (TPI) of a handsaw. Below, you’ll find an excerpt from my question in the comments, along with his prompt response.

“You mentioned that the numbers on the sawset represent the ppi on the saw. However, the contrary is true. It is widely taught and accepted that the numbers do not correspond to the ppi on a saw. Do you have any evidence to refute this claim, and what is your source?”

Graham’s response: “Some metal sawsets have rotating anvils with multifacetted faces at different angles numbered to conform to the expected angle of set for saws with that number of TPI for the individual saw. Not perhaps what is always required, which is why I explained the process of diminishing the produced set after setting with a file.”

Interestingly, this is the first time I’ve encountered this concept. Traditionally, I’ve believed the opposite, as it aligns with what we’ve been taught over the years. However, could we be mistaken, and perhaps Graham is onto something? I remain uncertain because he hasn’t substantiated his claim with historical evidence or cited the source of his knowledge, as I requested. I’ll provide the video link below for you to watch and form your own conclusions.

I recently read Traditional Jigs & Fixtures for Handtools, one of his books, and found it to be brilliant. Additionally, I’ll provide you with the link to his book store.

You can explore more of Graham Blackburn’s woodworking resources and books on his website. If you’re interested in other titles, feel free to check them out!

Jim Kingshott

Kingshott books and videos were produced in the 1990s, and I still find them to be an invaluable source of information. Today I purchased his book The Workshop: Designing, Building, Equipping Paperback – 1 March 1994. You can’t find it on Amazon but I did find it on Abesbooks, and it was only US$2.75 plus postage so it worked out to be about AU$26.

You may be wondering who this character is, right? Well, he was a master cabinetmaker, even though I don’t like to use the term “cabinetmaker” as the term is more in reference to those who make kitchens. He made furniture, and he was darn good at it too. His name wasn’t Jim; he was born Raymond John Kingshott on January 7, 1931, in England.

He grew up amongst woodshavings at his grandfather’s workshop. He was apprenticed as both a carpenter and furnituremaker in the 1940’s at A. J. Tracey & Co. Ltd., making him one of the last individuals to emerge from the system prevalent before World War II.

For over 50 years, Jim worked in the woodworking industry, making everything from coffins to aeroplanes, and until recently, he was apprentice master to the woodworking trade apprentices at the Royal Aircraft Establishment at Farnborough.

Jim’s forte was the making and use of handtools. He was a true master craftsman and probably did more to encourage traditional woodworkers in the UK than anyone else. He wrote and made several books and DVDs in the 1990s. One of the DVDs I was lucky enough to find on YouTube.

The book I purchased and mentioned above is one I’m looking forward to reading. I’ve never been satisfied with the layout of my workshop, and I’m hoping to gain some good information to help me out.

He has about ten books he’s written, and I will provide the link to them here: https://www.goodreads.com/author/show/955208.Jim_Kingshott

You cannot buy from the link provided, but if you search the title, some of them are still available. There are three books of interest that I’m eager to get my hands on: “Making & Modifying Woodworking Tools,” “Sharpening,” and “Woodworker’s Guide to Joints: An Illustrated Guide That Really Shows You How to Make Perfect Joints by Jim Kingshott (June 27, 1), paperback. The last one is more out of curiosity to see just how Jim executed each joinery technique by hand. I’m sure there will always be something new to learn.

For over 50 years, Jim worked with wood, from making coffins to aeroplanes. Had he still lived today, he would be 80 years in the trade.

Jim died on February 25th, 2002, after a long battle with cancer.

Jim’s grandson, Allan Kingshott, followed in Jim’s footsteps and is a qualified carpenter/joiner. So the family tradition of working wood continues.

What Is It?

I received an email enquiry about a particular desk, which has left me puzzled. The desk’s unique feature is its back, which is designed with three panels adorned with ripple mouldings, a detail I’ve never encountered before. The intricate ripple mouldings, which require a significant amount of time to create, suggest that the desk was not intended to be placed against a wall but to be viewed from all angles. Another peculiar aspect is that it has a single shelf without any dividers, ruling out the possibility of it being a postal desk. Given the number of history enthusiasts who follow my blog, I’m hopeful that someone will be able to shed light on this mystery.

The Purpose and Usefulness of a Kerfing Plane

Introduction

A kerfing plane is a specialised woodworking tool that has gained popularity among woodworkers for its unique functionality and precision. This tool was first introduced by Tom Fidgen in his book “Unplugged Workshop.”

Purpose of a Kerfing Plane

The primary purpose of a kerfing plane is to cut a kerf, or groove, around the perimeter of a board before re-sawing. This kerf serves as a guide for the saw blade, ensuring a straight and accurate cut. The kerfing plane was designed with the understanding that a saw will follow the path of least resistance. By creating this path, the kerfing plane helps eliminate saw drift, making re-sawing tasks much more reliable and accurate.

Design and Functionality

The kerfing plane typically consists of a saw blade attached to a body with a fence. The fence ensures the kerf is cut at a consistent distance from the edge of the board. Some kerfing planes have a fixed fence, meaning they can only cut a kerf at a specific distance from the edge. Others have an adjustable fence, allowing for greater versatility.

The depth of the kerf can also be adjusted, typically up to about 1/2 inch. This allows the user to control how deep the saw blade penetrates the wood, providing further control over the re-sawing process.

Usefulness of a Kerfing Plane

The kerfing plane is particularly useful for tasks that require a straight, accurate saw line. These tasks include re-sawing a plank, cutting off a box lid, and other similar jobs. The kerfing plane doesn’t need to saw right through a piece of wood; instead, it provides a guideline for a handsaw to finish off.

By creating a kerf, the kerfing plane makes these tasks easier and more precise. It ensures the saw blade follows a straight path, reducing the likelihood of errors and improving the quality of the finished product.

Conclusion

In conclusion, the kerfing plane is a valuable tool in the woodworker’s arsenal. Its ability to create a guiding kerf makes it indispensable for tasks that require precise, straight cuts. Whether you’re a professional woodworker or a hobbyist, the kerfing plane can enhance the quality of your work and make your woodworking tasks more enjoyable.

Simple Saw Vice

All you need are three pieces of 2×4 and a couple of lengths of hardwood 1×2s. There are no critical dimensions, so just use what you have. For most handsaws, a 18in long appliance is about right. The height of the uprights depends on where you plan to set up the appliance; I aim for the saw teeth to be at elbow height for comfortable sharpening.

Cut long machine V notches in the top of each upright, as shown in the sketch, and drill a hole at the point of the V to reduce the chance of splitting. Now bevel two 22in hardwoods 1×2s so that, sandwiched together, they match the angle of the V-notch.

To use the appliance, hold the wedge strips on either side of the blade about 1/2in down from the teeth, and tap the blade and strips down into the notches. A tap from below will release the whole thing.

The Laborious Art of Hand Tool Woodworking and Its Impact on the Spine

Introduction

Hand tool woodworking is commonly perceived as strenuous and challenging. Indeed, it’s all that and even more. To gloss over it would be a kindness to those teaching the craft, and to some extent, it’s worth it. However, when it comes to your health, it’s definitely not worth compromising.

The Laborious Nature of Hand Tool Woodworking

Since my first introduction to woodworking back in 1977, I’ve always had a fascination with the craft and dabbled in it. It wasn’t until 1998 that I took it seriously and started a woodworking business that was modelled around handwork through the use of traditional woodworking hand tools. The early years were filled with learning experiences and challenges, but the passion for woodworking kept me going. As I honed my skills and craftsmanship, I found joy in creating unique pieces that showcased the beauty of natural wood. Each project became a labour of love, blending traditional techniques with modern design sensibilities.

Over time, the woodworking business evolved, and I had the opportunity to collaborate with other artisans and woodworkers, exchanging ideas and techniques that enriched my own practice. Embracing the time-honoured methods of woodworking brought a sense of fulfilment and connection to the heritage of the craft, instilling a deep appreciation for the artistry and meticulous attention to detail required.

The journey from a personal fascination with woodworking to building a thriving business centred on traditional hand tools has been incredibly rewarding. It’s a testament to the enduring appeal of craftsmanship and the timeless beauty of handmade wooden creations. Looking ahead, I am eager to continue exploring the boundless possibilities of woodworking, preserving its legacy while infusing it with innovation and creativity.

Somewhere down the line, my back took a turn for the worse. It started gradually in my younger years, and the fix was simple. Nothing short of a back massage will fix it. They say you must exercise your muscles, and what better exercise than physically planing and sawing all day long for six days a week?

The reality was that I was wearing it out quicker than it would have naturally

Hand tool woodworking requires a great deal of physical effort. The use of hand tools such as saws, chisels, and planes involves repetitive motions that can be physically demanding.This laborious nature of hand tool woodworking can be attributed to the manual effort required to shape and manipulate wood without the aid of power tools.

The process of hand tool woodworking involves a variety of tasks, each with its own set of challenges.For instance, planing a piece of wood to a desired thickness or ripping a board to width requires not only skill but also physical strength and endurance.

Impact on the Spine

The physical demands of hand tool woodworking can have implications for the spine. Prolonged periods of standing, bending, lifting, and twisting can lead to various spinal disorders. These may include back pain, sciatica, and other conditions that cause discomfort in the neck, arms, and legs.

Over the years, my commitment to the craft and my promise of “handmade” have taken a toll on my back as I strained over the workbench. My decision not to incorporate any machinery for the laborious task of breaking down the stock has resulted in significant discomfort. The pain was so severe that I was incapacitated for two weeks, unable to walk or even perform simple tasks like dressing myself. My insistence on purity was, in retrospect, a mistake. Machinery wasn’t created solely for profit, although it undoubtedly plays a significant role. Its primary purpose was to alleviate laborious tasks, minimise physical strain that could lead to injuries, and expedite the work process. While I enjoy the process of building a project entirely by hand, it just isn’t worth the risk if you have underlying health issues.

Conclusion

While hand tool woodworking can be a laborious task, it is also a rewarding craft that many find fulfilling. However, it’s important for woodworkers to be mindful of the potential impact on their spine and take preventative measures. This could include regular breaks, using ergonomic tools, and incorporating exercises that strengthen the back muscles.

Remember, sharp tools make all the difference, and so does a healthy spine.

Happy woodworking!

Disclaimer: This blog post is intended for informational purposes only. If you’re experiencing back pain or other health issues, please seek advice from a healthcare professional.